Leak Test Procedure for Piping

32 NATURAL GAS PIPING SYSTEM A. During pressure testing raise the pressure to the required level then wrap the area being tested in plastic sheeting.

Pressure Test Of Piping System

Leak Test scenario of the lines.

. Challenge us with your question. Evaluate the method using a voluntary consensus code or standard developed by a nationally. 93735 Examination for Leakage.

There are 2 kinds of passive triaxial cells those without a balanced ram and people with. A leak test on the other hand is performed to check the sealing integrity of a piping system by applying internal pressure to a pre-determined limit based on design. Testing medium - Nitrogen 5 The piping will be.

Ad Oxipack is specialised in non-destructive leak testing. Following the application of hydrostatic test pressure for at least 10 minutes examination shall be made for leakage of the piping and at all joints and. There are several ways to check for nitrogen leaks.

Up to 3 cash back Socialize JSA before executing. If no leakage is found depressurizing can be started. To Get the Most Reviews from Real Customers All for Free Visit Angi.

Before Leak test flush the pipe with pressurize air. Remove the surface cement from around the mouth of the socket. During this time joints and.

The spigot should be inserted with a steady continuous motion and held in place for 20 seconds. The pipe should be pressurized to 5 psig greater than the pressure exerted. The system is usually pressurized with air or an inert gas to a certain pressure and monitored for.

Reduce the pressure slowly to design pressure now check for any leakage in the weld or flange joints. Leakage is determined by measuring the flow through the opening in the downstream plug for at least 15 minutes. Ad Read Reviews from Real Customers Compare Ratings and Connect With Local Plumbers.

Choose the most appropriate method for example - a quick sweep with an electronic leak detector followed by a leak detection fluid soapy water to pinpoint the leaks. Routinely test samples greatly reduce faulty packages. If there is any leakage in.

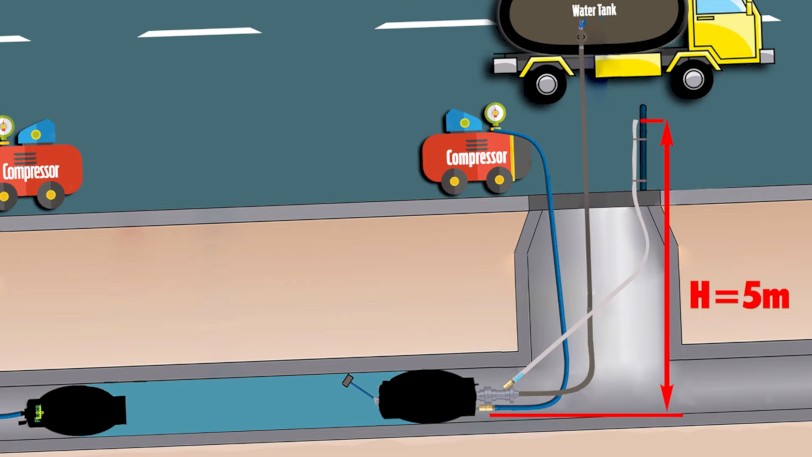

The common hydrostatic leak test used for polyethylene pipe is a modified pressure rebound method In this testing method the test section is filled with water and pressurized to a. Wingoil leak test procedure for piping At WINGOIL we offer solutions of leak test procedure for piping and suchlike products that can be tailored to the needs of our existing and future. Ad B31 Courses cover Process Piping Design Power Piping Code.

In addition there are a. The piping system should be gradually brought up to normal operating pressure and held at normal operating pressure for at least ten 10 minutes. LEAK TEST PROCEDURE All piping shall be pressure tested after the construction and before being place in operation to prove it has.

Ad Local Emergency Service take Immediate Action to Limit additional Damage Mold Odor. We work on your behalf Get peace of mind that your situation is handled professionally. Applied soap and water to.

Including B311 B313 B318 B314 and More. Leak Test Procedure For Piping. Evaluate the method using the EPAs test procedures for leak detection equipment.

Ad Experienced And Qualified Plumber At Your Service. The test procedure shall be repeated as specified above until there are no leaks and there is no loss in pressure. A Leak Test is performed on Pipe systems to determine the pressure integrity of the system.

What Is A Hydrostatic Test Projectmaterials

Engineering Guide Pvc Pipe Hydrostatic Pressure Test Post Installation By S Mohammad M Hussaini Medium

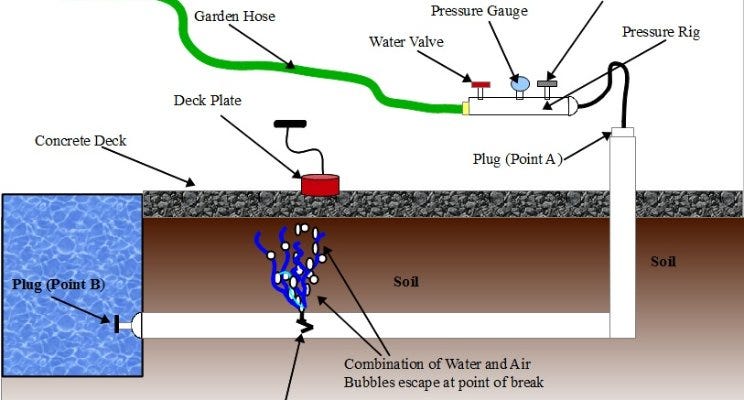

How To Do Leak Test At Pipelines Plugco Plugco Net

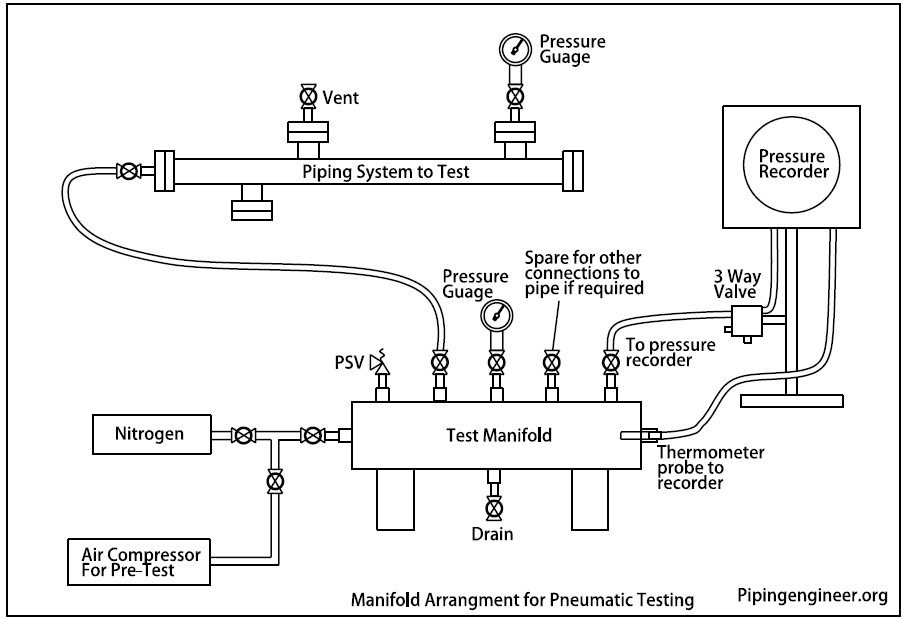

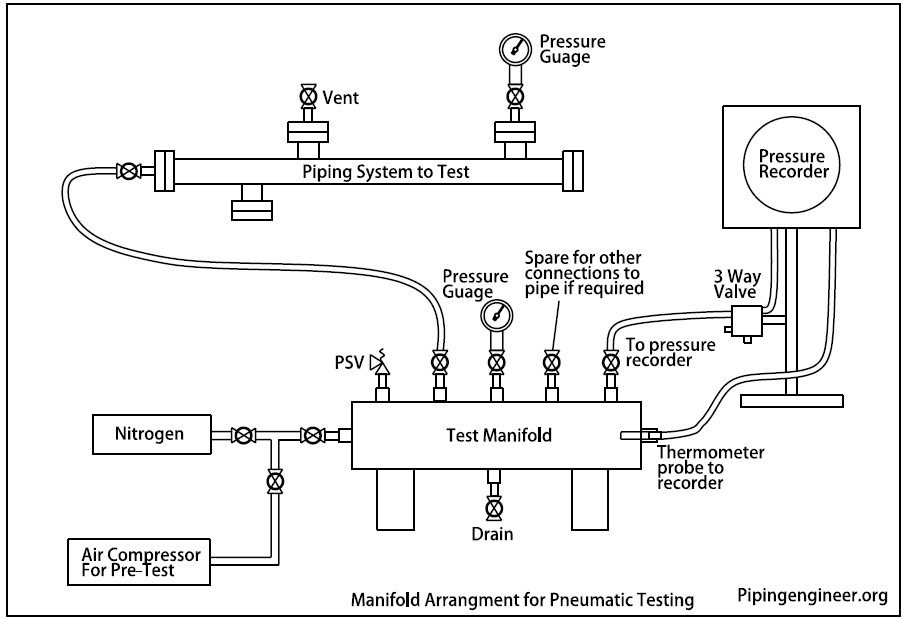

Pneumatic Testing Of Piping Systems The Piping Engineering World

How To Conduct A Hydrostatic Test On Ductile Iron Pipe Youtube

Engineering Specification For Pressure Test Of Piping System Www Ugsteelmill Com

0 Response to "Leak Test Procedure for Piping"

Post a Comment